A desiccant (adsorption) air dryer is critical in industrial compressed air systems. It removes water vapor to deliver clean, dry air and protect downstream equipment, instruments, and end products.

However, like any mechanical system, a desiccant air dryer can develop recurring faults—often showing up as high outlet dew point, unstable pressure, excessive purge loss, frequent alarms, or unexpected shutdowns.

This guide breaks down the most common desiccant air dryer problems, explains the root causes, and provides practical fixes and prevention strategies to reduce downtime and extend dryer life.

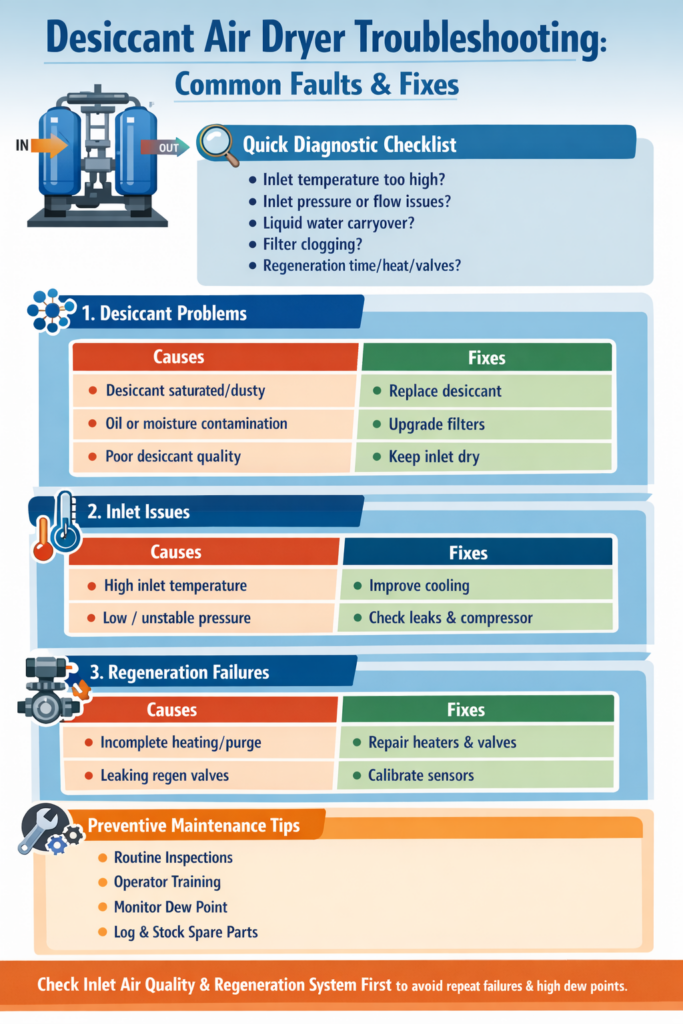

Quick Diagnostic Checklist (Start Here)

Before you open the dryer or replace parts, check these five items—many “dryer failures” are actually system-condition problems:

Inlet temperature: Is the air entering too hot (aftercooler not performing)?

Inlet pressure & flow: Is pressure stable and within dryer design range? Is flow exceeding rating?

Liquid water carryover: Is the water separator/drain working? Any water slugs entering the dryer?

Pre-filters / after-filters: Any pressure drop indicating clogging?

Regeneration: Is purge/heat/time sufficient? Any valve leakage?

If any of these are out of spec, correct them first—otherwise faults will repeat even after replacing desiccant or valves.

1) Desiccant-Related Problems

1.1 Desiccant Exhaustion (Loss of Drying Capacity)

What you’ll see

Outlet dew point rises gradually over time

Dryer struggles to meet required dew point even though cycles appear normal

Why it happens

Desiccant saturation over service life: pores fill with moisture and capacity drops

Oil contamination or particulate fouling: oil aerosols and dirt coat the desiccant surface

Low-quality desiccant: shorter life, higher dusting, early performance decline

How to fix it

Inspect desiccant condition and replace saturated/contaminated media

Upgrade upstream filtration (especially oil coalescing) to protect the bed

Choose high-quality desiccant appropriate for your target dew point and operating conditions

Prevention tips

Keep accurate service records (hours, dew point trend)

Control inlet air quality and prevent oil/water carryover

1.2 Desiccant Clogging, Dusting, or Channeling

What you’ll see

Higher pressure drop across the tower

Reduced drying performance even with “fresh” desiccant

Dust in downstream filters, mufflers, or valves

Why it happens

Desiccant attrition (powdering) from poor quality media, vibration, or frequent pressure shocks

High moisture load / liquid water carryover accelerates breakdown and clumping

Harsh ambient conditions (high temperature, high humidity) increase stress on the bed

How to fix it

Replace heavily dusted/clumped desiccant; clean towers if necessary

Fix upstream causes: aftercooler, separator, drains, filters

Ensure proper installation: correct fill level, support screens, and flow distribution components

Prevention tips

Avoid inlet liquid water at all costs—this is a top cause of rapid desiccant failure

Stabilize operating pressure and reduce sudden flow surges

2) Inlet Temperature and Pressure Problems

2.1 Inlet Temperature Too High

What you’ll see

Dew point increases, especially during hot seasons

Dryer “looks normal” but cannot meet dew point spec

Why it happens

Aftercooler or cooling system underperforms (fouling, low cooling water, poor airflow)

High ambient temperature and inadequate ventilation around equipment

How to fix it

Ensure the dryer receives air within its rated inlet temperature range

Service the aftercooler and improve ventilation

Add/upgrade a pre-cooler if the compressor discharge temperature is consistently high

Prevention tips

Treat inlet temperature as a performance “multiplier”: hot inlet air dramatically increases moisture load

2.2 Inlet Pressure Too Low (or Unstable)

What you’ll see

Tower pressure cannot build to system pressure

Drying performance drops; switching becomes abnormal

Purge losses may become excessive or inconsistent

Why it happens

Clogged inlet filter elements increase restriction

Compressed air piping leaks or undersized lines cause pressure drop

Compressor output instability or insufficient capacity

How to fix it

Replace/clean clogged filter elements (verify differential pressure)

Repair leaks and confirm correct pipe sizing

Service the compressor and confirm stable discharge pressure

Prevention tips

Track pressure drop across filters and towers as a routine KPI—rising DP is an early warning

3) Regeneration System Problems

3.1 Incomplete Regeneration (Insufficient Heat/Time/Purge)

What you’ll see

Dew point worsens after a few cycles

One tower seems to “never fully recover”

Increased alarms related to dew point or cycle timing

Why it happens

Heater failure (heated dryers): damaged heating element, wiring fault, protection trip

Regeneration valves malfunction: leakage, sticking, blockage

Control logic/sensor errors: wrong timing, faulty temperature/pressure feedback

Purge flow too low (heatless dryers): wrong orifice, blocked muffler, incorrect settings

How to fix it

Verify regeneration parameters: temperature, time, purge flow, cycle sequence

Repair/replace heaters, solenoids, actuators, or faulty valves

Check sensors and calibrate/replace if readings are unstable

Inspect mufflers/silencers and purge flow components for blockage

Prevention tips

A dryer can only dry as well as it regenerates—regeneration health is the core of long-term stability

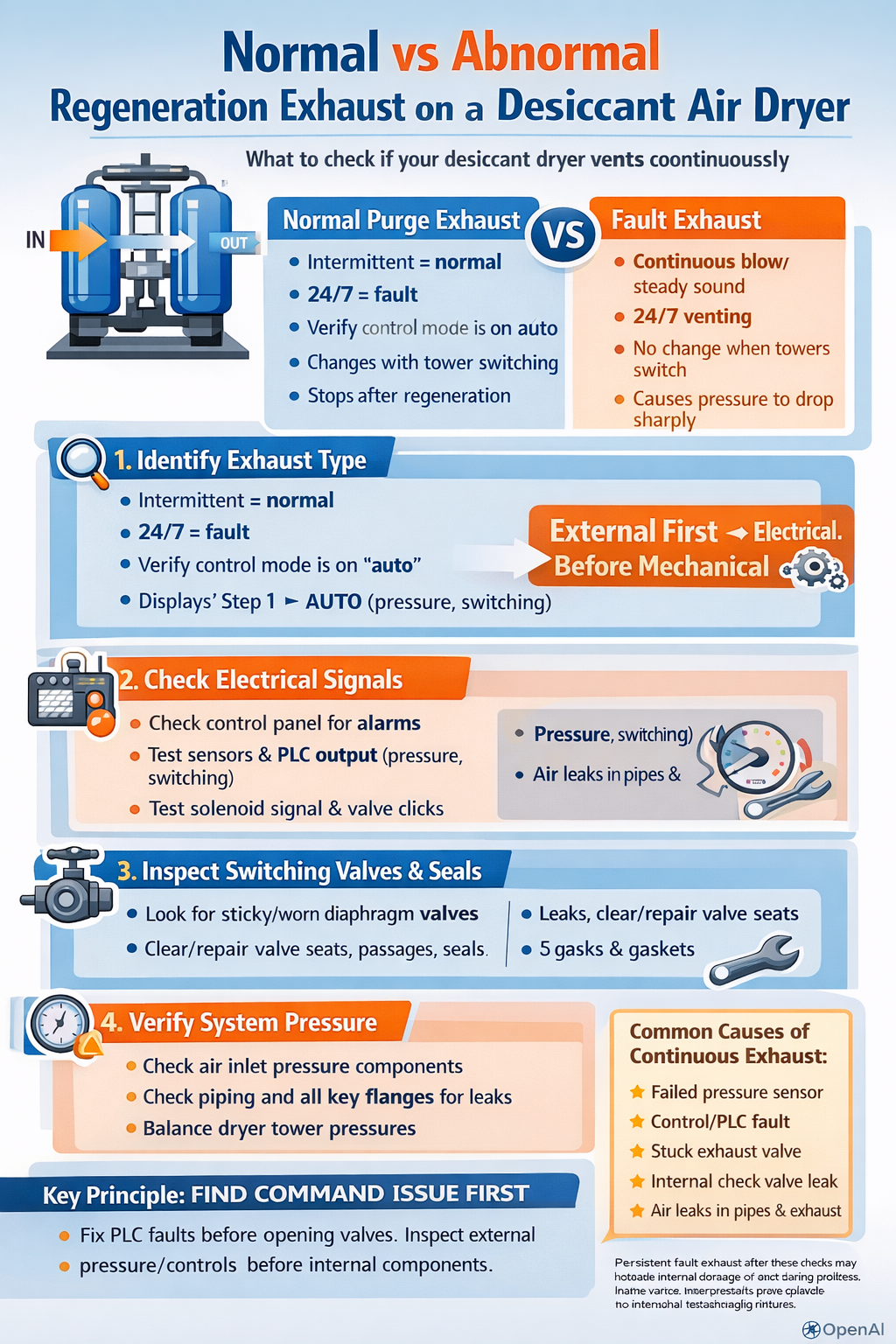

3.2 Regeneration Valve Leakage

What you’ll see

Unexpected air loss, higher energy cost

Poor regeneration efficiency and unstable dew point

Audible leaking or continuous venting

Why it happens

Worn sealing surfaces, debris on seats

Actuator issues, solenoid faults, mechanical sticking

How to fix it

Overhaul or replace leaking valves; clean seats and remove contamination sources

Inspect actuators/solenoids and ensure correct control signal and air supply (if pneumatically actuated)

Prevention tips

Install and maintain upstream filtration to keep debris and oil away from valve internals

4) Electrical and Control System Problems

4.1 Power Supply Faults

What you’ll see

Dryer fails to start, random resets, intermittent alarms

Heaters/solenoids behave unpredictably

Why it happens

Loose wiring, aged power cables, poor grounding

Failed switches, contactors, breakers, or protection devices

How to fix it

Inspect terminals and wiring; tighten and re-terminate as needed

Replace damaged switches/contactors; verify stable voltage within specification

4.2 Controller / PLC or Sensor Faults

What you’ll see

Regeneration cycle won’t start/stop correctly

Wrong switching timing or inconsistent tower behavior

Temperature/pressure/dew point readings jump or drift

Why it happens

Program logic errors, parameter misconfiguration

Faulty temperature/pressure sensors or wiring issues

How to fix it

Review parameters (cycle time, heater setpoint, purge setting) and restore known-good configuration

Test sensors and replace failed components; verify signal integrity

5) Other Common Issues

5.1 Filter Blockage

Impact

Lower inlet pressure → weaker drying performance

Higher outlet dew point and reduced system efficiency

Fix

Replace or clean filter elements on schedule

Improve pre-filtration to match inlet air quality (dust/oil load)

5.2 Abnormal Noise

What it may indicate

Damaged valves, failed mufflers/silencers

Airflow impact due to sudden restriction or incorrect piping

Electrical problems such as motor overload (if applicable)

Fix

Inspect mechanical components and replace damaged parts

Reduce vibration and resonance with proper mounting/support

Diagnose electrical faults and correct overload/connection problems

6) Preventive Maintenance Strategy (Reduce Failures and Extend Dryer Life)

To lower failure rates and extend service life, implement a structured maintenance system:

Routine inspection plan: daily checks + scheduled cleaning + preventive replacement

Operator training: ensure correct operation, safety, and alarm response

Use OEM or verified-quality parts: valves, seals, sensors, desiccant, filter elements

Environmental control: avoid extreme heat and humidity; ensure ventilation

Condition monitoring: track inlet/outlet pressure, temperature, dew point, and differential pressure

Failure log & root cause tracking: record time, cause, fix, and outcome to prevent repeats

Spare parts inventory: keep critical spares (valve kits, solenoids, sensors, filter elements, drains)

Conclusion

Desiccant air dryer faults are rarely “random.” Most repeat failures come from inlet conditions (temperature, pressure, water/oil carryover), desiccant health, or regeneration integrity.

By combining correct troubleshooting with a preventive maintenance strategy, you can significantly reduce downtime, stabilize dew point performance, and protect the entire compressed air system.