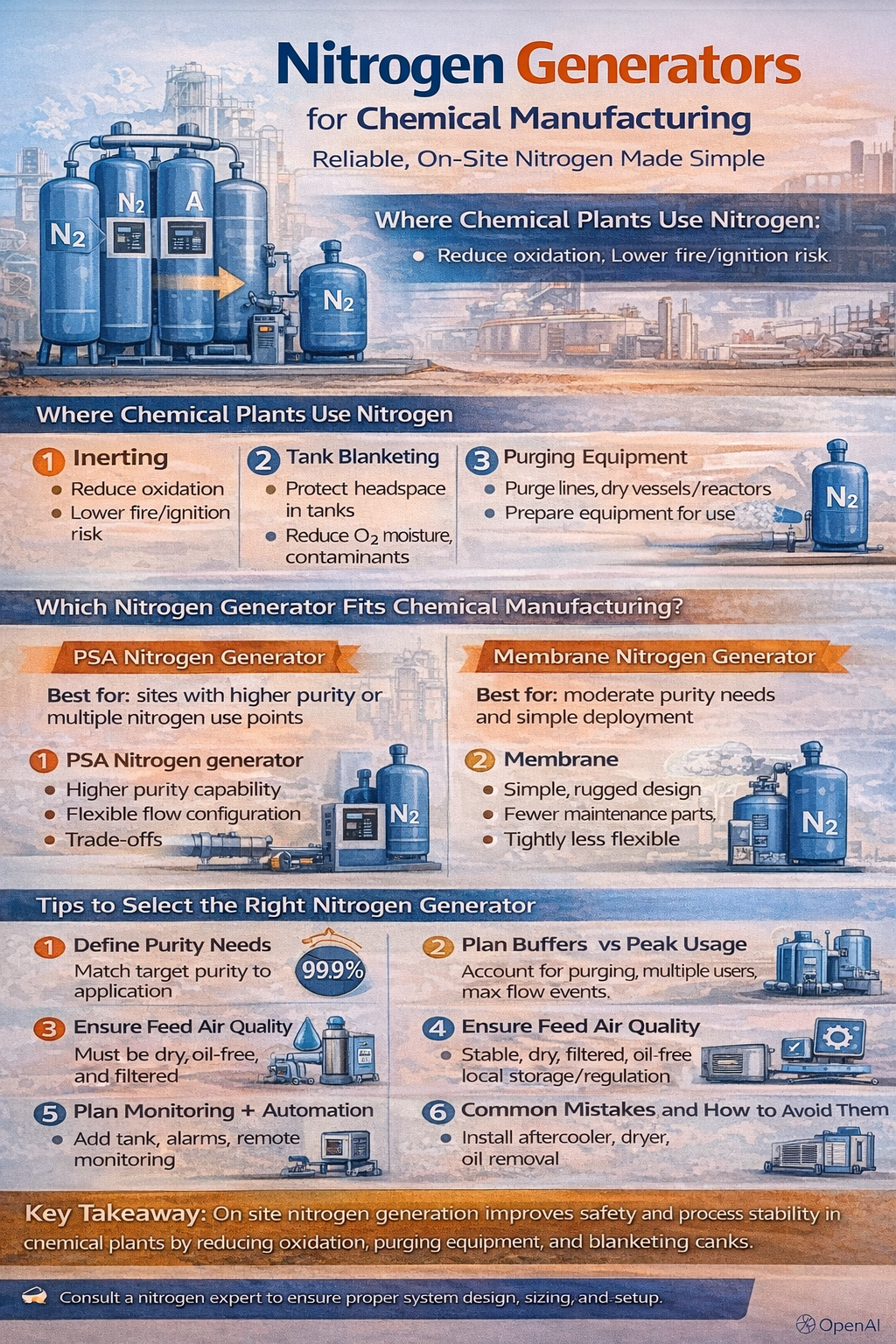

In chemical manufacturing, nitrogen isn’t a “nice to have.” It’s often the difference between stable production and oxidation, contamination, pressure swings, or even serious safety incidents. That’s why more plants are moving from delivered nitrogen (cylinders or liquid nitrogen) to on-site nitrogen generation—most commonly with a nitrogen generator for chemical manufacturing based on PSA or membrane technology.

This blog explains where nitrogen is used in chemical plants, why on-site generation is attractive, and how to choose the right nitrogen generator for your processes—without overspending or underspecifying.

Why Chemical Plants Use Nitrogen So Heavily

1) Inerting and oxygen displacement (safety + product protection)

Many chemicals and solvents react with oxygen or moisture. Nitrogen creates a low-oxygen environment that helps:

reduce oxidation of raw materials and intermediates

improve product consistency and color stability

lower the risk of ignition in flammable vapor spaces

protect catalysts and sensitive chemistries

2) Tank blanketing (keep air out, keep quality in)

Nitrogen blanketing maintains a protective headspace in:

storage tanks (solvents, monomers, oils, resins)

day tanks and dosing tanks

intermediate bulk tanks and reactor feeds

It helps prevent oxygen ingress, moisture pickup, and unwanted reactions—especially during temperature changes and filling/emptying.

3) Purging and drying of lines, vessels, and reactors

Nitrogen is widely used for:

start-up purging (remove air before introducing process gases/vapors)

shutdown purging (clear residual flammable/corrosive gases)

equipment drying after cleaning or maintenance

pressure testing and leak checks (when appropriate to plant standards)

4) Pressure transfer and agitation support

Nitrogen can provide inert pressure for:

transferring liquids between vessels

pushing product through filters and lines

supporting certain mixing/blanketing strategies where air is unacceptable

The Case for On-Site Nitrogen Generation in Chemical Manufacturing

Delivered nitrogen can work—but chemical production often demands continuous, predictable, scalable supply. An on-site nitrogen generator typically wins when you have steady consumption, multiple nitrogen points, or frequent purging.

Key benefits

Lower long-term nitrogen cost

You produce nitrogen from compressed air, reducing dependence on deliveries, cylinder handling, and LN₂ logistics.

Better supply security

No delivery delays, cylinder shortages, or weather/transport disruptions impacting production.

Stable process control

Consistent nitrogen flow/pressure supports more stable blanketing and purging performance.

Safer operations

Less cylinder movement and manual handling; cleaner, more controlled supply architecture.

PSA vs Membrane vs Liquid Nitrogen: What Fits Chemical Plants Best?

PSA nitrogen generators (Pressure Swing Adsorption)

Best for: medium-to-high purity needs and broad chemical plant usage

Strengths:

commonly chosen for tank blanketing, inerting, purging, and process support

flexible purity/flow configurations (within system design)

good fit when purity requirements are higher or variable

Watch-outs:

needs good compressed air quality (dry, filtered; oil control is critical)

requires scheduled maintenance (valves, CMS performance monitoring)

Membrane nitrogen generators

Best for: simple, rugged supply where ultra-high purity is not required

Strengths:

fewer moving parts, often simpler maintenance

fast response and compact footprint

Watch-outs:

purity typically lower than PSA for the same economics

efficiency drops at higher purity targets

Delivered liquid nitrogen (LN₂) / bulk nitrogen

Best for: very high purity or very large peak demand, or where utilities are limited

Strengths:

very high purity available

convenient for massive short-term demand spikes

Watch-outs:

ongoing delivery costs and contract volatility

storage, safety, and handling requirements

supply chain dependency

Practical takeaway:

For many chemical manufacturers, PSA is the “workhorse” choice because it balances purity capability, operating cost, and flexibility for multiple nitrogen applications.

How to Choose a Nitrogen Generator for Chemical Manufacturing

This is the section most buyers search for—because the wrong sizing shows up as unstable tank pressure, low purity alarms, or insufficient purge capacity.

1) Define your nitrogen applications first

List each use case and decide whether it is:

continuous (blanketing, steady inerting)

intermittent (batch purging, maintenance drying)

peak-driven (large vessel purge events)

One generator can serve multiple points, but sizing must account for peak demand or include buffer storage.

2) Specify purity correctly (don’t guess)

Purity needs vary a lot in chemical manufacturing:

Some blanketing and transfers work fine at moderate purity.

Certain oxidation-sensitive products, catalysts, or hazardous atmospheres may require higher purity targets and tighter oxygen limits.

If you’re unsure, define purity using:

required oxygen concentration in the protected space

product sensitivity and quality targets

safety/risk assessment requirements and plant standards

3) Calculate flow with a “real plant” approach

Don’t size only from average consumption. Include:

purge volumes (vessel size, desired purge cycles, purge method)

simultaneous users (multiple tanks/lines at once)

leakage and venting allowances (especially on older systems)

future expansion (new lines, extra storage, higher throughput)

4) Confirm delivery pressure at the point of use

Your generator outlet pressure must cover:

regulator setpoints

piping losses

filters and safety devices

peak flow conditions (pressure drop increases with flow)

5) Don’t ignore compressed air quality (it decides reliability)

A nitrogen generator is only as good as its feed air. Chemical plants should pay attention to:

dryness (stable dew point to prevent water-related issues)

oil aerosol control (protects adsorption media/membranes and analyzers)

particulate filtration (protects valves and instrumentation)

If your compressed air system is unstable, plan upgrades: aftercooling, separators, drains, filters, and a dryer.

6) Add the right “stability hardware”

For chemical manufacturing, these are often worth it:

Nitrogen buffer tank (smooths peaks, stabilizes pressure, supports purge events)

Oxygen analyzer + alarms (confidence in purity)

Auto purity control / economy modes (reduce energy use when demand is low)

Redundancy strategy (critical lines may need backup supply or dual trains)

7) Materials and environment considerations

Chemical plants may have corrosive atmospheres or washdown areas. Evaluate:

enclosure rating and corrosion protection

stainless options where contamination/corrosion matters

electrical and area classification requirements per site rules (always follow local standards)

Common Use Cases in Chemical Manufacturing (Examples)

Solvent storage tank blanketing to prevent oxygen ingress and reduce oxidation

Reactor purging before introducing flammable vapors or reactive gases

Pipeline and filter housing purging during product changeovers

Drying equipment after cleaning to reduce moisture-related quality issues

Inert transfer of intermediates to minimize contamination and unwanted reactions

Maintenance Expectations (What Plant Engineers Want to Know)

A well-designed nitrogen generator should be predictable to maintain. Typical items include:

filter element replacement (feed air filtration)

valve maintenance kits (PSA systems)

periodic analyzer calibration/verification

checking dew point/air quality upstream

monitoring adsorption media performance over time (PSA)

The goal is to prevent the two most common headaches:

purity drift (often caused by air quality issues or valve wear)

capacity shortfall (usually from undersizing or growth in demand)

FAQs (Google-Style)

Is a nitrogen generator safe for chemical plants?

Yes—when engineered correctly and operated under plant safety procedures. Proper design includes oxygen monitoring where required, appropriate venting, and compliance with site standards and local regulations.

What purity do I need for chemical manufacturing?

It depends on the application (blanketing vs purging vs sensitive reactions). Define purity based on oxygen limits, product sensitivity, and your plant’s safety requirements—then size the generator accordingly.

PSA or membrane—which is better?

For many chemical plants, PSA is preferred when higher purity or flexibility is required. Membrane is often chosen for simpler applications where moderate purity is sufficient and simplicity is a top priority.

Do I need a nitrogen storage tank?

Often yes—especially if you have large purge events or fluctuating demand. A buffer tank stabilizes pressure and reduces the need to oversize the generator.

Conclusion: Treat Nitrogen as a Production Utility, Not a Consumable

For chemical manufacturing, a nitrogen generator is more than a cost-saving device—it’s a reliability and process-stability tool. When you size it around real demand, protect it with clean/dry compressed air, and add the right monitoring and buffer capacity, on-site nitrogen can significantly improve:

safety margins

product consistency

uptime and operational control

long-term operating cost

If you want, tell me your target nitrogen purity, flow rate (Nm³/h or m³/min), delivery pressure, and whether you need nitrogen mainly for blanketing, purging, or process use—and I’ll draft a Google-friendly “selection + sizing” version tailored to your exact application (including an FAQ section and a short meta description ready for publishing).