In many industrial applications, moisture in compressed air is not just an inconvenience—it is a serious risk. Excess moisture can cause corrosion, system failures, and product contamination. A regenerative air dryer is specifically designed to remove moisture to extremely low dew points, ensuring stable, high-quality compressed air for critical processes.

What Is a Regenerative Air Dryer?

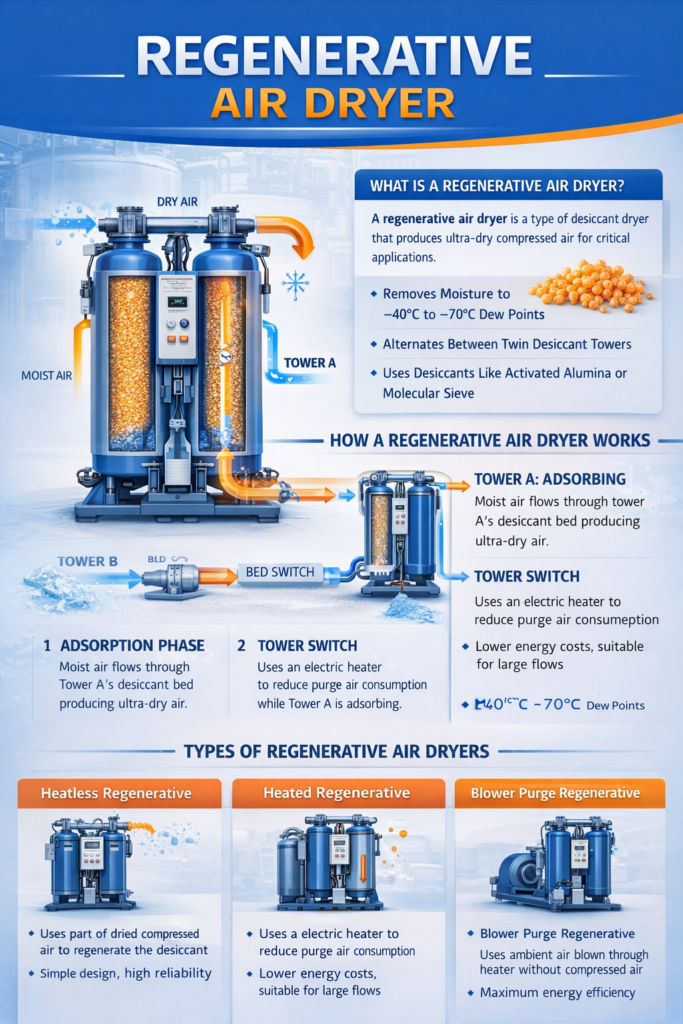

A regenerative air dryer is a type of desiccant air dryer that removes water vapor from compressed air by passing it through a bed of desiccant material, such as activated alumina or molecular sieve. While one desiccant bed dries the compressed air, the other bed undergoes regeneration to remove absorbed moisture. This alternating process ensures continuous delivery of dry air.

Regenerative air dryers are widely used in industries where ultra-dry air and consistent performance are essential.

How a Regenerative Air Dryer Works

The drying and regeneration process typically follows these steps:

Adsorption Phase

Moist compressed air flows through the active desiccant bed, where water vapor is adsorbed, producing dry air at the outlet.Regeneration Phase

The saturated desiccant bed is regenerated using either purge air, heated air, or external energy to remove the absorbed moisture.Switching Cycle

The dryer automatically switches between the two desiccant towers, maintaining continuous operation and stable dew point performance.

Depending on the regeneration method, regenerative air dryers can be classified into several types.

Types of Regenerative Air Dryers

Heatless Regenerative Air Dryers

These dryers use a portion of the dried compressed air to regenerate the desiccant.

Advantages:

Simple design

High reliability

No external power for heating

Applications: General industrial use where compressed air availability is sufficient.

It uses high-performance pneumatic valves, good adsorbent materials, and electronic controllers, which are simple to operate, have low operating noise, and have long service life.

Heated Regenerative Air Dryers

Heated dryers use electric heaters or blower systems to regenerate the desiccant, reducing compressed air loss.

Advantages:

Lower purge air consumption

Improved energy efficiency

Suitable for large flow rates

Applications: Large manufacturing plants and continuous-duty systems.

2. The heater is equipped with pressure protection to prevent the heater from dryburning, which increases the service life of the heater.

3, Low operating noise;

4. High-performance pneumatic valves are used:

Blower Purge Regenerative Air Dryers

These systems use ambient air blown through heaters to regenerate the desiccant, eliminating compressed air loss during regeneration.

Advantages:

Maximum energy efficiency

Lowest operating cost over time

Applications: High-capacity industrial systems with strict energy requirements.

Key Benefits of a Regenerative Air Dryer

Ultra-Low Dew Points: Achieves pressure dew points of -40°C or even -70°C

System Protection: Prevents corrosion, freezing, and moisture-related failures

Process Stability: Ensures consistent air quality for sensitive applications

Long Equipment Life: Reduces wear on pneumatic tools and downstream equipment

Compliance Support: Meets ISO 8573-1 air quality standards for critical industries

Typical Applications

Regenerative air dryers are commonly used in:

Food and beverage processing

Pharmaceutical and medical manufacturing

Electronics and semiconductor production

Chemical and petrochemical industries

Outdoor or low-temperature environments

Choosing the Right Regenerative Air Dryer

When selecting a regenerative air dryer, consider the following factors:

Required pressure dew point

Air flow capacity and system pressure

Ambient and inlet air conditions

Energy efficiency and operating costs

Maintenance requirements and service accessibility

A properly sized and well-maintained regenerative air dryer ensures reliable performance and long-term cost savings.

Conclusion

A regenerative air dryer is a critical component for any compressed air system that requires ultra-dry, high-quality air. By combining advanced desiccant technology with reliable regeneration methods, these dryers provide consistent performance, protect equipment, and support demanding industrial applications. Investing in the right regenerative air dryer helps ensure operational efficiency, product quality, and long-term system reliability.